Commercial composting

Turning green waste into nutrient-rich compost at Parkgate Farm

Our certified open-air composting facility at Parkgate Farm near Purton processes thousands of tonnes of green waste each year

By transforming this material into high-quality compost, we help improve soil health, support agriculture, and contribute to the circular economy across the South West, including Berkshire, Bristol, Gloucestershire, Somerset, and Wiltshire.

What is compost?

Compost is a nutrient-rich soil improver made from biodegradable green waste. Through a controlled natural process, materials like grass cuttings, leaves and hedge trimmings break down into a stable organic product that enhances soil structure and fertility.

How the composting process works

We only accept green waste at Parkgate Farm. We do not accept food waste, treated wood, or invasive plant species, such as Japanese Knotweed. This strict input control ensures the final product is free from harmful contaminants and unwanted seeds.

What's our composting process?

%20Large%20(1).jpg?width=2000&height=1414&name=Hills%20Waste%20(Isometric%20compost%20illustration%20-%20FINAL)%20Large%20(1).jpg)

Composting in action

Turning green waste into compost

Inspection and contamination removal

Incoming loads are visually inspected, and any plastics, metals or non-compostable materials are removed. Waste that fails to meet quality standards is rejected.

Shredding and batching

The material is shredded to a consistent size and arranged into long rows called piles (known as "windrows"). Each can hold up to 800 tonnes.

Composting (sanitisation and stabilisation)

Over approximately 10 weeks, the compost is actively managed:

-

- Turned regularly to maintain oxygen levels

- Monitored for temperature (up to 65°C) and moisture

- Maintained in compliance with PAS 100:2018 and REAL certification standards

These high temperatures help kill pathogens such as E. coli and prevent weed growth.

Maturation

The material is left to cool and stabilise during a final two-week phase, ensuring it is fully mature.

Screening and quality testing

The compost is screened into two grades:-

- 0–16mm: for agriculture, horticulture, landscaping, and land restoration

- 0–40mm: typically used in land restoration and agriculture

Regular lab tests are conducted to verify nutrient levels, absence of pathogens, and product performance (e.g. tomato germination tests).

Use and application

The finished compost is used by local farmers, land managers and landscapers to enrich soil, support plant growth, and reduce dependence on synthetic fertilisers.

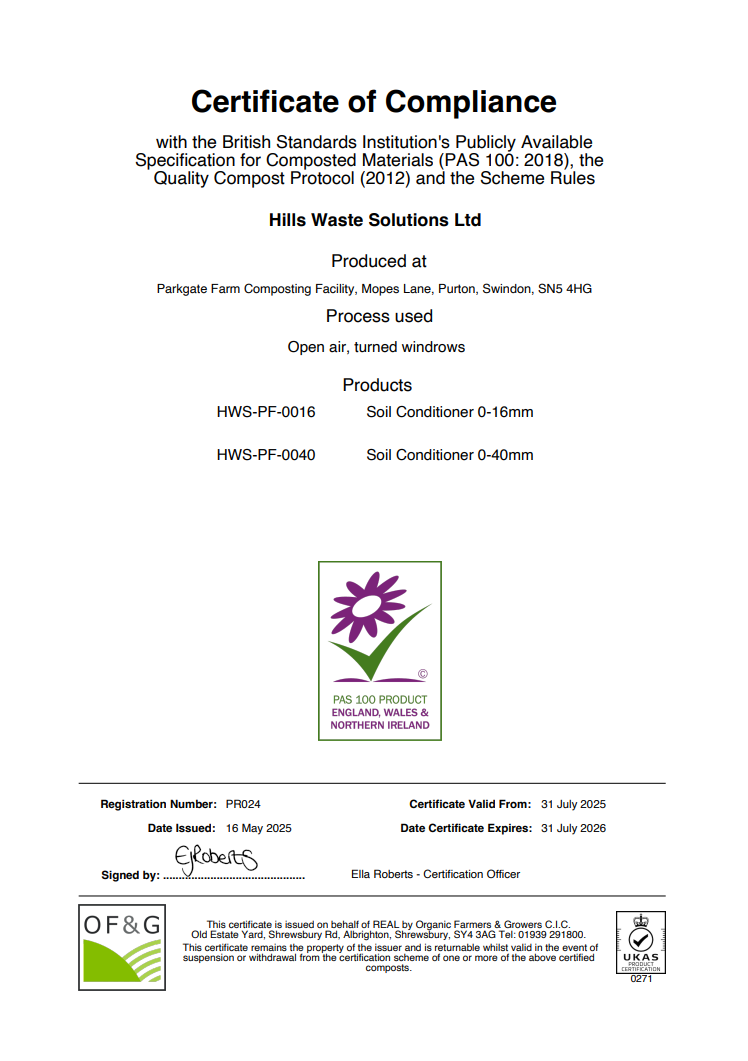

Certified composting quality you can trust

Our composting process adheres to:

These certifications cover input material quality, processing standards, testing, and full traceability.

Compost is produced under our Quality Management System (ISO 9001:2015) and overseen by trained operatives and a dedicated compliance manager.

Our HACCP procedures ensure consistency and safety at every stage.

Latest news

View all

Collaboration between Hills Waste and Meiyume helps drive sustainability goals

February 2026Meiyume and Hills Waste collaboration helps drive forward sustainability and net zero ambitions.

Continue reading

New College Swindon appoints Hills Waste Solutions

April 2025New College Swindon has appointed Swindon-based Hills Waste Solutions as its waste and recycling con...

Continue reading

Hills continues CO₂ reductions with Salisbury HVO roll out

March 2025Hills Waste Solutions’ commercial transport depot at Amesbury, near Salisbury is the latest site to ...

Continue reading